LOTIS® QC-X

Skip the molds. Go Straight to the bottom line.

What Makes the QC-X Superior to Everything Else On the Market?

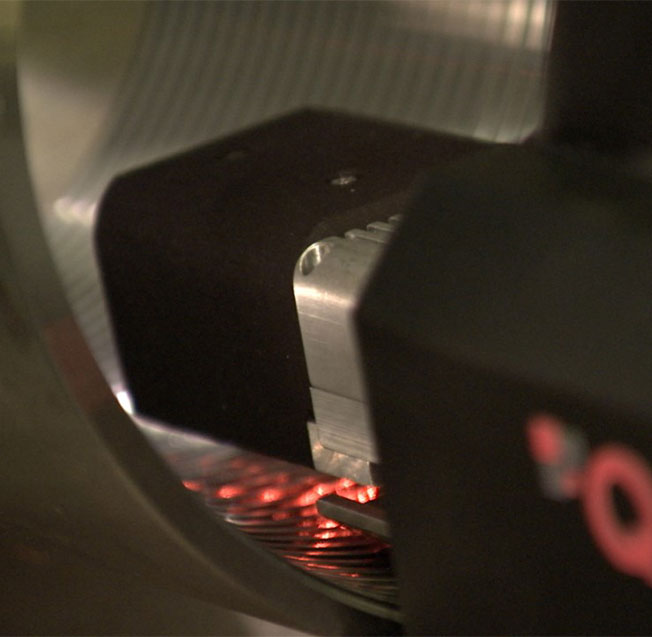

The LOTIS® QC-X Thread Profiler provides OCTG thread cutters with an electronic mold at a cutting station. The LOTIS® QC-X’s automated laser measurement technology eliminates the wasted time and lost production inherent in the current molding process.

How Will the LOTIS® QC-X Save Time and Money While Increasing Accuracy & Output?

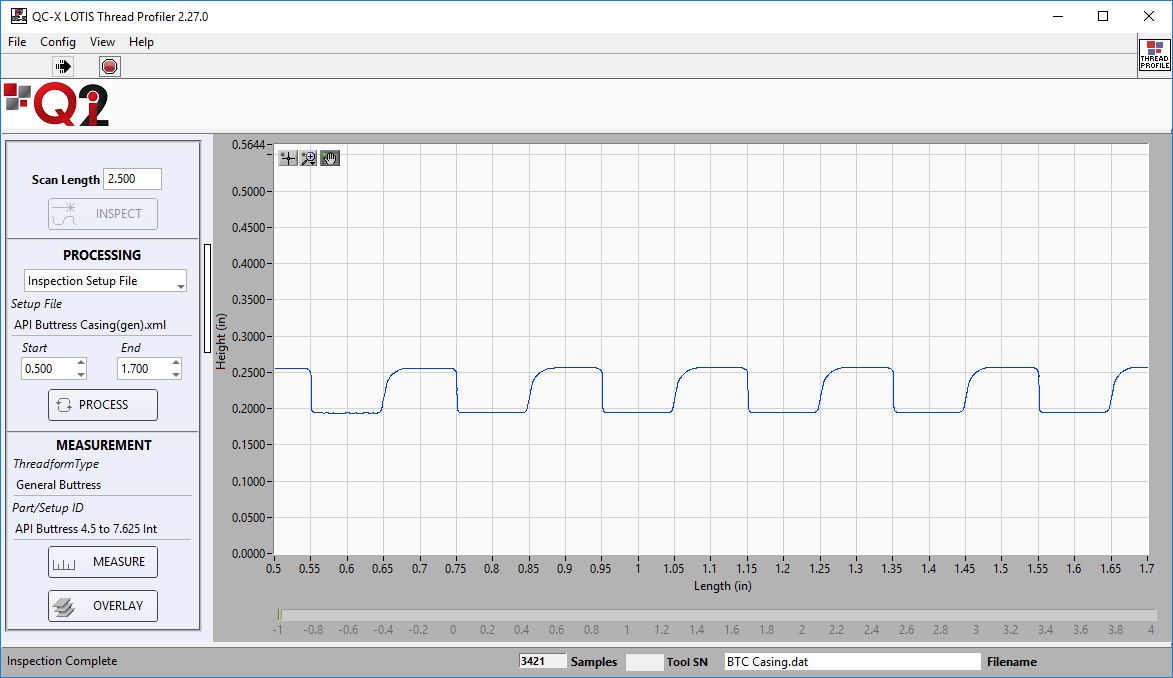

Simplicity of operation is key. The LOTIS® QC-X Thread Profiler is designed to function in a thread-cutting environment at a workstation. Both the hardware and software have been engineered for ease of use by any operator:

• Inspects API, Semi-Premium and Premium Threads

• Dual laser system can be mounted in any orientation

• Quick and easy to learn

• Reduces Human Factors issues

• Digital profile archived for traceability

• Speeds up shift start time

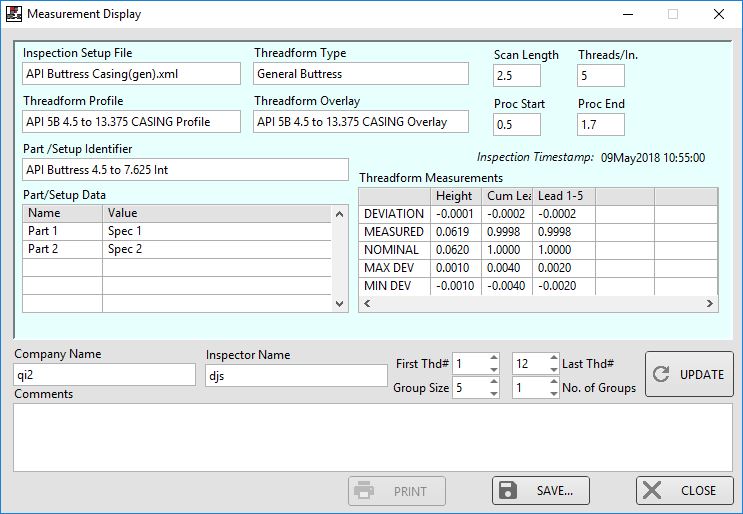

Easy-to-Read User Interface

Make quick and accurate decisions with our clear and simple Measurement Display.

Your New Process with the LOTIS® QC-X:

- An operator can attach, scan, and unattach in less than 45 seconds

- The LOTIS® QC-X captures measurement of Height, Lead, Cumulative Lead, and Profile Geometry

- Superimposes an electronic mold onto an electronic overlay

Industry-Leading Accuracy & Detail

The scanned profile offers levels of data you simply won't find in a traditional thread molding process.